Headworks Screening Products

Headworks International designs and manufactures a complete line of headworks equipment for wastewater treatment plants. The following information is just a sample of the technology available from Headworks, more complete information is available by contacting us or by visiting their website at www.headworksinternational.com.

Headworks Partial Screening Products List

- MS Series Bar Screen - Multi-rake screen

- Perforator™ Screen - Perforated plate screen

- Eliminator™ Screen - Internally-fed perforated plate screen

- Screwpactor™ - Screenings compactor

- Transpactor™ - Screenings transport and compaction

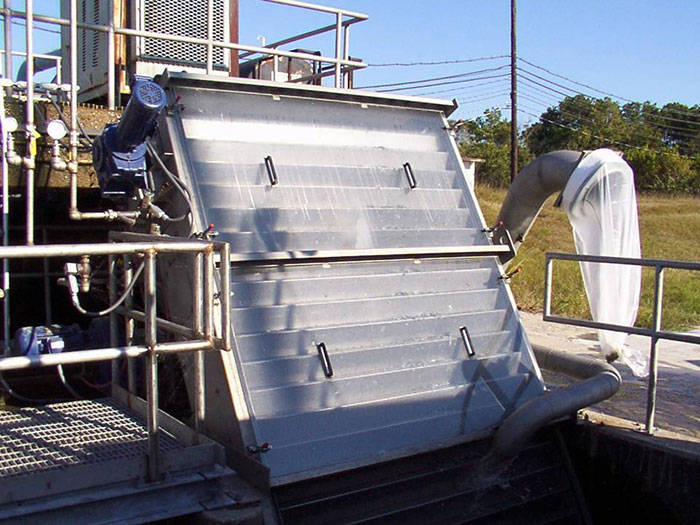

Headworks MS Bar Screens

- Openings as fine as 3/16” (4mm)

- Strength of a coarse screen, performance of a fine screen

- Automatic Reversing feature makes the unit Self-Cleaning

- Short Cleaning Intervals eliminate blinding factors in sizing

- Low Maintenance, low life-cycle costs

- High hydraulic capacity at 2 MGD/sq. ft. screen area

- 2-Speed operation can handle the heaviest solids loads

- Tapered screen-field bars for low head loss

- All stainless steel chain and sprockets for durability and low maintenance

Headworks Perforator™ Screen

- Effective screen cleaning without a messy brush

- Dual-Surge™ spray system reduces carry-over

- Multi-Plex™ side seal prevents screenings by-passScreen as fine a 1/8” (3mm)

- All Stainless steel chain requires no lubrication

Headworks Eliminator™ Screen

- Screen as fine as 0.080" (2mm)

- Stainless steel screen elements for strength

- Mult-Plex™ side seal prevents screenings by-pass

- All stainless steel chain requires no lubrication

- Dual-Surge™ spray system for effective cleaning.

Transpactor™ and Transporter™ conveyors

Screwpactor™ screenings compactor

Screwpactor™

Headworks Bio Products

Headworks BIO Inc. a division of Headworks International offers biological wastewater treatment processes that can be used as secondary treatment for a variety of municipal and industrial applications. For over a decade, their team has researched and developed wastewater treatment systems and technology for moving bed processes, fixed-film wastewater treatment, and integrated fixed-film activated sludge (IFAS) wastewater systems.

The result of this in-depth research and development is their Moving Bed Biofilm Reactor (MBBR) technology – a biological wastewater treatment process– that can be adapted and designed for any application.

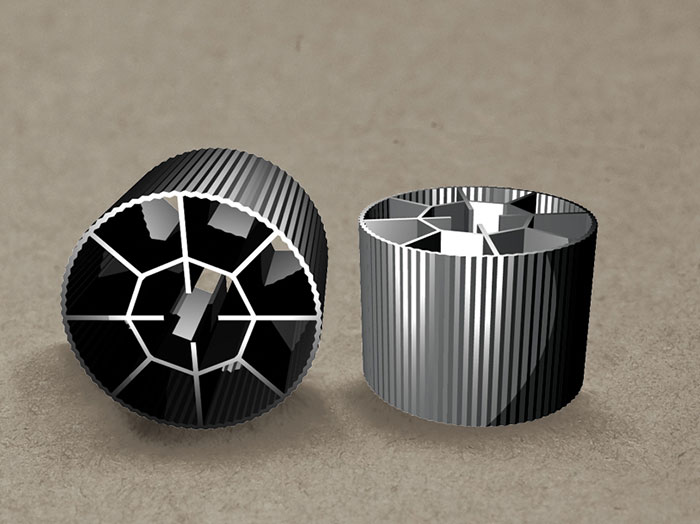

MBBR /IFAS technology employs thousands of polyethylene biofilm carriers operating in mixed motion within an aerated wastewater treatment basin. Each individual biocarrier increases productivity through providing protected surface area to support the growth of heterotrophic and autotrophic bacteria within its cells. It is this high-density population of bacteria that achieves high-rate biodegradation within the system, while also offering process reliability and ease of operation.

MBBR/IFAS systems deliver a flexible, cost-effective, and easy-to-operate means to address current wastewater requirements and the expandability to meet future loads or more stringent discharge requirements within a compact design.

With approximately 20 years of experience in municipal and industrial applications, Headworks BIO is one of the oldest MBBR/IFAS technology providers in the biological wastewater treatment sector. For more information on their Bio products please visit their website at www.headworksinternational.com

Headworks AC450 MBBR Media

Headworks AC920 MBBR media

Headworks media with attached Bio-film

Headworks Integrated Treatment (HIT) System.

A modular, compact wastewater treatment system designed for smaller communities and industries. The HIT system provides a complete solution - screening, grit removal, MBBR or IFAS treatment, clarification, tertiary filtration and disinfection.

Moving Bed Biofilm Reactor (MBBR)

MBBR process improve reliability, simplifies operation, and requires less space than traditional wastewater treatment systems.

Integrated Fixed-Film Activated Sludge (IFAS)

This process is typically installed as a retrofit solution for conventional activated sludge systems that are at or beyond original design capacity.